Product Description

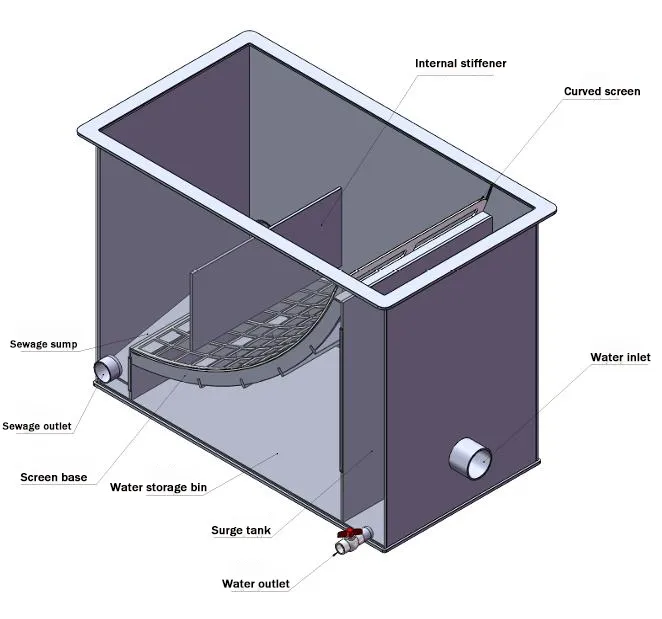

Guangzhou Qili Environmental Equipment Co., Ltd.Sieve filter is mainly composed of box assembly and arc screen, which deals with water treatment,the water flow can be customized and made of high-quality PP materials. The suspended solids in the water are separated by a screen.

Working Principle

The water to be treated first enters the buffer area through the inlet of the unpowered arc filter and flows into the arc filter net from the top of the screen.The suspended matter in the water is trapped by the screen, and the water that does not contain more than 74μm of suspended matter after filtration enters the storage area, and finally enters the next equipment from the outlet of the unpowered arc filter or returns to the aquaculture water body.

When the suspended matter in the curved screen network accumulates to a certain amount, it will cause the water permeability of the screen network to decrease, resulting in the filter water directly flowing to the sewage tank above, direct discharge causes water loss; At this time, the curved screen should be replaced in time to ensure the positive filtering effect, and the replaced net should be washed with a high-pressure water gun, and the back of the screen should be washed first and then the front of the screen.

Product Feature

1. This product does not need to move, is an energy saving and environmental protection product;

2. The screen mesh is made of stainless steel mesh with high quality and unique technology, with small aperture, low resistance, strong water passing capacity, zero consumption if the screen is not blocked;

3. The shell is made of high quality plastic material, strong anti-corrosion and durable.

Technical Specification

Koi Pond Sieve Filter- No lid, 1 screen as standard | |||||||||

Model | Flow/h | Length/mm | Wide/mm | Height/mm | Filtration accuracy(Micron) | Inlet/mm | Outlet/mm | Sewage outlet/mm | Overflow port /mm |

QL-HX-5 | 5m³/h | 854 | 454 | 550 | 75 | 50 | 75 | 50 | 50 |

QL-HX-10 | 10m³/h | 1174 | 574 | 700 | 75 | 75 | 90 | 50 | 75 |

QL-HX-20 | 20m³/h | 1274 | 674 | 850 | 75 | 110 | 110 | 75 | 110 |

QL-HX-30 | 30m³/h | 1384 | 784 | 980 | 75 | 110 | 160 | 75 | 110 |

QL-HX-60 | 60m³/h | 1484 | 1034 | 1100 | 75 | 160 | 200 | 75 | 160 |

Installation and operation instructions

Installation requirements

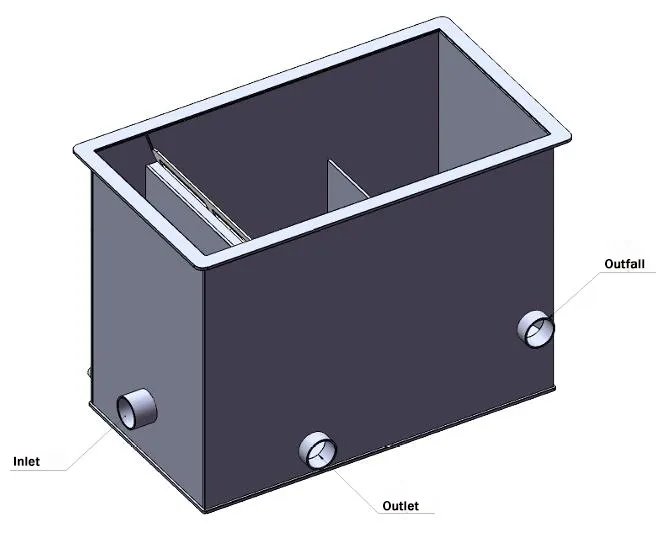

1.Equipment installation ground level, solid foundation

2. Align the water inlet pipe and water outlet pipe with their dimensions when connecting to the device

3.Ensure that the device is properly installed

Debugging and use instructions

1.Check that the inlet and outlet valve of the unpowered arc filter is still open and the blowdown valve is closed

2.Check the seal of each pipe

Matters needing attention

1.Overflow water needs to be returned to the breeding tank.

2.The sump outlet should be kept normally open when the equipment is being cared for, and can be closed when no one is looking after it, but it must be kept flooded

The mouth is always open.

3.The curved screen needs to be replaced in time to prevent the water from overflowing directly back to the breeding tank without filtration or discharging at the sewage collection tank outlet,resulting in water loss.

4.The curved screen must be cleaned immediately when it is replaced, so as not to dry the residual feed and feces on the screen, resulting in difficult screen clean it up.

Equipment maintenance and repair

Equipment inspection points | Inspection cycle | Remark |

Check whether the curved screen is blocked | Ornamental pool 1-2 days, aquatic 4-5 hours | It is recommended to have an extra screen |

Whether each bin body is polluted | Variable time |

|

Sealing condition of each pipeline | Variable time | If there is water leakage, replace it in time |