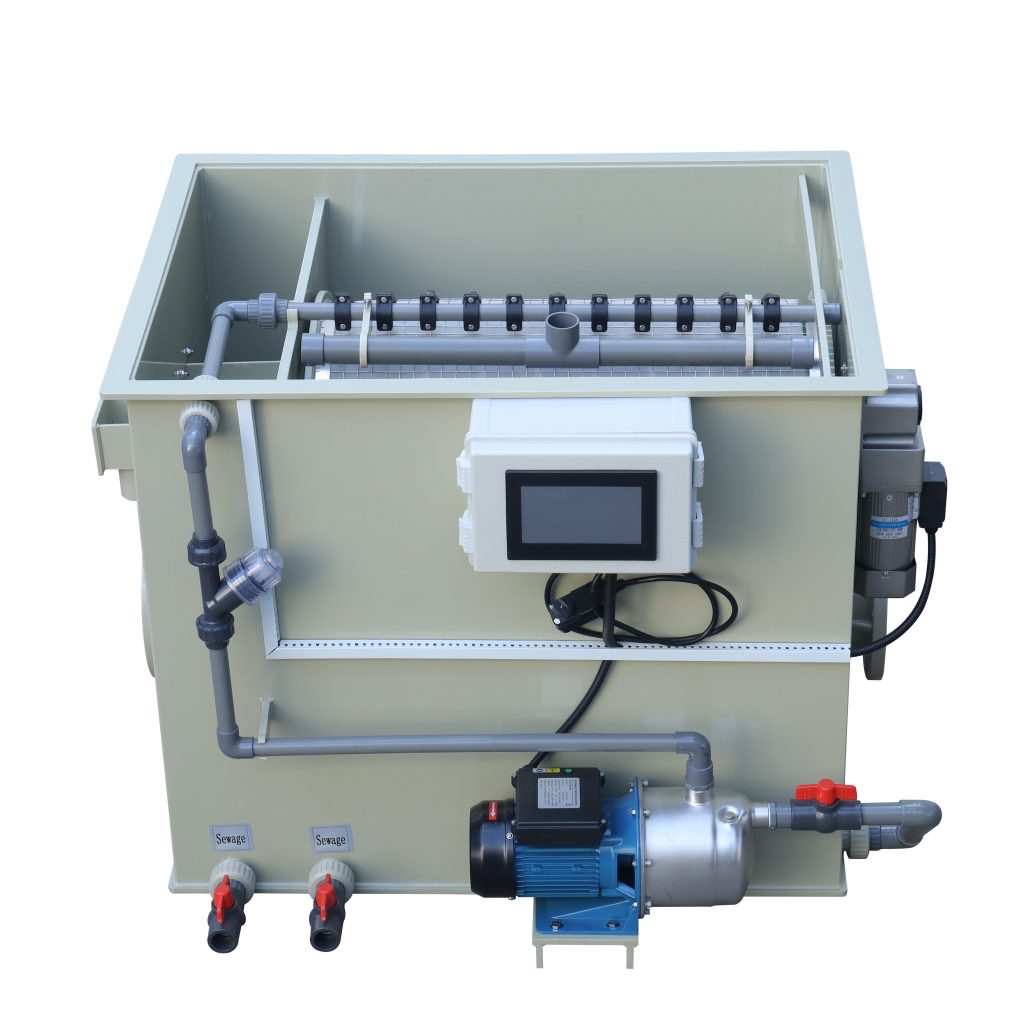

Drum filters are essential components in various industrial processes, serving to remove solid particles and impurities from liquids. As technology continues to advance, it becomes crucial for businesses to upgrade their equipment to enhance performance, efficiency, and control. In this article, we will explore two key upgrades for drum filters: the integration of stainless steel checker net to protect the drum screen and the implementation of an intelligent touch screen control box.

Stainless Steel Checker Net: Safeguarding the Drum Screen

The integration of stainless steel checker net presents a significant advancement in drum filter technology. This upgrade serves as a protective barrier for the drum screen, preventing damage from large or abrasive particles. By incorporating this feature, businesses can significantly extend the lifespan of their drum filters while minimizing maintenance and replacement costs.

Moreover, the use of stainless steel ensures durability and corrosion resistance, making it an ideal material for industrial applications. This upgrade not only enhances the reliability of the drum filter but also contributes to a more sustainable and cost-effective operation in the long run.

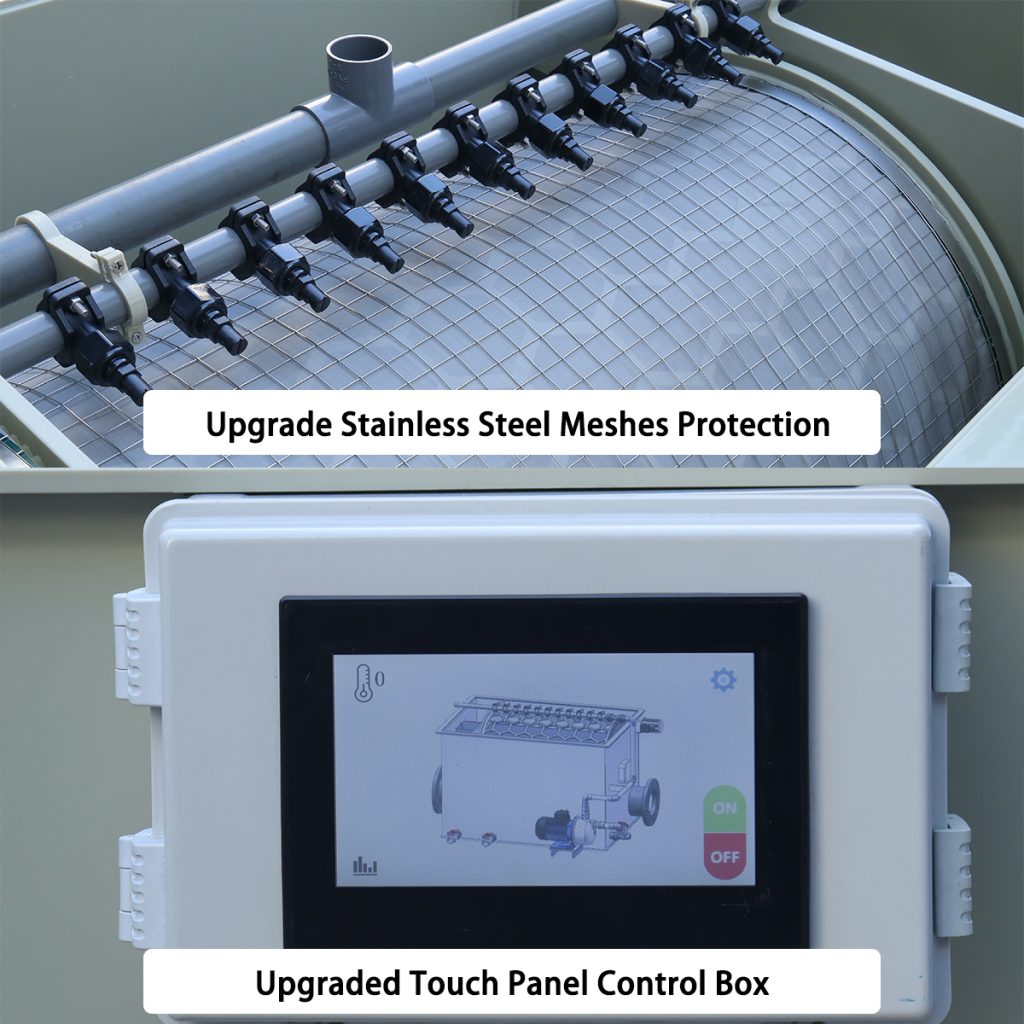

Intelligent Touch Screen Control Box: Streamlining Operation and Monitoring

The introduction of an intelligent touch screen control box revolutionizes the way operators interact with drum filters. With intuitive user interfaces and advanced monitoring capabilities, this upgrade offers real-time insights into the filtration process, allowing for proactive adjustments and troubleshooting.

Furthermore, the integration of automation and data analytics enables predictive maintenance, optimizing the performance of the drum filter and reducing downtime. This level of control and oversight empowers businesses to maximize efficiency, minimize operational costs, and ensure consistent quality in their processes.

Considerations and Implementation

While these upgrades offer compelling benefits, it is essential for businesses to consider the initial investment and compatibility with existing systems. Conducting a thorough cost-benefit analysis and consulting with industry experts can help in evaluating the feasibility and potential return on investment for these upgrades.

Additionally, the implementation of these upgrades may require specialized expertise for installation and calibration. Therefore, businesses should ensure proper training and support for their personnel to leverage the full capabilities of the enhanced drum filters.

Conclusion

In conclusion, the integration of stainless steel checker net and the adoption of an intelligent touch screen control box represent significant advancements in drum filter technology. These upgrades not only enhance the reliability and performance of the equipment but also contribute to operational efficiency, cost savings, and quality assurance. As industries continue to evolve, embracing these technological innovations can position businesses for sustained success and competitiveness in the market.